ara :

+86 18681515767

ara :

+86 18681515767

e-posta :

marketing@jtspeedwork.com

e-posta :

marketing@jtspeedwork.com

ara :

+86 18681515767

ara :

+86 18681515767

e-posta :

marketing@jtspeedwork.com

e-posta :

marketing@jtspeedwork.com

01. bizim ürünlerimiz

Sıcak ÜrünlerShenzhen jietong teknoloji co., ltd. radyo frekansı tanımlama (rfid) geliştirme, üretim ve satışına odaklanan bir yüksek teknoloji şirketidir.

her zaman bir adım daha fazla!

Shenzhen Jietong Technology Co., Ltd, UHF RFID donanımının Ar-Ge, üretim ve satışına odaklanan bir yüksek teknoloji şirketidir. Jietong, mühendislerin 10 yıldan fazla Ar-Ge deneyimine sahip olduğu kendi Ar-Ge ekibine sahiptir. Müşteriye en iyi hizmeti ve ürünü sunmak için Jietong, proje, satış sonrası servis ve teknoloji desteği için tüm çözümü sunmak için sürekli olarak gelişmektedir. Jietong , UHF RFID Impinj R2000/TM200 çoklu etiket okuma okuyucusu , UHF RFID tek etiket okuma okuyucusu , UHF RFID uzun menzilli Okuyucu , UHF RFID orta menzilli okuyucu , UHF RFID masaüstü okuyucu/yazıcı , UHF RFID okuyucu modülü gibi ana ürün gruplarına sahiptir. , UHF RFID El Tipi Okuyucu , UHF RFID anteni , UHF RFID kartı ve Etiketi vb. Jietong, kullanıcıların üstünlüğü ilkesine sahiptir ve pazar odaklı, yeni teknolojiye ve yüksek kaliteye bağlıdır, müşterilerimize en son teknolojiyi, en iyi ürünleri, rekabetçi, samimi hizmeti sunacağız. Kendisini müşterilerinin ve tedarikçilerinin işlerinin güvenilir, yenilikçi ve güvenilir bir parçası olarak kabul ettirdik.

02. neden bizi seçmelisiniz

bizim avantajımızshenzhen jietong teknoloji co. ltd., Ar-Ge, radyo frekansı tanımlama (rfid) üretimi ve satışına odaklanmış bir yüksek teknoloji şirketidir. Şeylerin internet okuyucu uhf rfid serisi özel profesyonel. jietong, mühendislerin 10 yıldan fazla ar-ge tecrübesine sahip olduğu kendi ar-ge ekibine sahiptir. Müşteriye en iyi hizmeti ve ürünü sunmak için jietong, proje, satış sonrası hizmet ve teknoloji desteği için tüm çözümü sunmak için sürekli gelişme içindedir.jietong, uhf rfid modülü, rfid el okuyucu, uhf rfid okuyucu, otopark orta menzilli rfid okuyucu, uhf erişim kontrol okuyucu, uhf anteni, uhf kartları ve etiketi vb. içeren ana ürün gruplarına sahiptir.jt uhf rfid okuyucu zaten araç yönetiminde yoğun olarak kullanılmaktadır, ortamın kullanımı ayrıca fabrika için personel yönetimi, depo için ağırlık yönetimi, depo ve araç için erişim kontrolü, giyim yönetimi, tütün lojistik yönetimi, akıllı kütüphane yönetimi, üretim hattı tanımlama yönetimi, varlık içerir yönetim vb.jietong, kullanıcıların üstünlüğü ilkesine sahiptir ve pazar odaklı, yeni teknolojiye ve yüksek kaliteye bağlıdır, müşterilerimize en son teknolojiyi, en iyi ürünleri, rekabetçi ve içtenlikle hizmet sunacağız.

profesyonel

profesyonel

Ar-Ge ekibi 10 yıldan fazla deneyime sahiptir;

ürün

ürün

düşük maliyetli, orta ve yüksek kaliteli ürün sunmak;

kalite

kalite

kendi markalı ürün için ulusal patent koruması

hizmet

hizmet

2 yıl garanti ve 3 yıl maliyet-bakım;

03. proje vakaları

ÇÖZÜM&VAKABu çözüm sayfası, müşterilerin Jietong Technology ürünlerini kullanarak uygulama yükleme ve yönetme sorununu çözmelerine yardımcı olur. Aşağıdakiler dahildir: Araç yönetimi UHF kişisel sistem yönetimi Üretim hattı yönetimi Lojistik Yönetimi Varlık Yönetimi Depo yönetimi Çevresel temizlik araçları yönetir Akıllı kitaplık yönetimi

RFID Technology in the Renewable Energy Sector: Applications and Opportunities 1. Introduction As the global renewable energy industry expands, efficient asset management, supply c...

daha fazla oku

araç yönetimiÇin ekonomisinin terapötik gelişmesiyle birlikte insanların yaşam standartları yükseliyor; arabanın toplam mülkiyeti de hızla büyümeye başladı. şu anda, araç yönetimin...

daha fazla oku

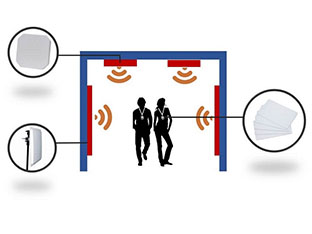

uhf rfid personel yönetim sistemi>> sisteme genel bakışuzun mesafeli kart personel yönetim sistemi, uhf rfid teknolojisi, internet teknolojisi ve uygulama teknolojisinin birleşimi ...

daha fazla oku

üretim hattı yönetimiDaha kaliteli ürünler üretmek için, üretim maliyetlerini düşürürken ve iso9000 gereksinimlerini karşılarken, üreticiler, üreticilerin rfid uygulamasını gerekti...

daha fazla oku

agv arabası yol kılavuz yönetimiüretim seviyesi ve artan müşteri talebi ile birlikte, çeşitli lojistik sistemleri, lojistik sistem cirosunun verimliliğinin nasıl artırılacağı, işçi...

daha fazla oku

varlık rfid yönetim sistemisistem görünümüVarlık artırma, dağıtım, depolama, elden çıkarma vb. dahil varlık yönetimini manuel olarak gerçekleştirmenin yolu, işletmeler ve bağlı kur...

daha fazla oku

04. Etkinlikler

son HaberlerShenzhen jietong teknoloji co., ltd. radyo frekansı tanımlama (rfid) geliştirme, üretim ve satışına odaklanan bir yüksek teknoloji şirketidir.

05. ücretsiz danışmanlık

mesaj bırakınÜrünlerimizle ilgileniyorsanız ve daha fazla ayrıntı öğrenmek istiyorsanız, lütfen buraya bir mesaj bırakın, size en kısa sürede cevap vereceğiz.

telefon : +86 18681515767

Whatsapp : +8618681515767

e-posta : marketing@jtspeedwork.com

12/F, Building A, No. 6, Shiben Road, Shiyan Street, Bao'an District, Shenzhen, Guangdong, China-518108

telif hakkı © 2026 Shenzhen Jietong Technology Co.,Ltd. her hakkı saklıdır.

ipv6 ağı desteklenir